Jednou z nejdůležitějších částí přenosu elektrické energie jsou transformátory, které provádějí proces známý jako elektromagnetická indukce. Jsou to integrované součásti mnoha elektrických systémů a nachází se v mnoha různých tvarů a velikostí. Existují různé druhy transformátorů, ale nejčastější, které se používají v distribučních a energetických systémech, jsou: Distribuční transformátory, Energetické nebo STP/STP Úkoly: Zajistit, aby bylo možné číst spotřebitele (100 MW), pokud mají inženýry.

Rozdíl mezi distribučními a výkonnostními transformátory. Tyto jsou typy transformátorů podle jejich účelu. Tyto transformátory distribuují energii obyvatelům a firemním subjektům z regionálních síťových systémů, takže mohou dosahovat různých výstupních napětí pro elektrifikaci strojů. Nicméně se výkonnostní transformátor používá k ovládání (regulaci) napětí v elektřinovém přenosovém systému a dokáže spravovat vysoké proudy efektivněji než distribuční transformátor.

Proč je energetická účinnost důležitá v transformátorech

Účinnost využití energie je důležitým faktorem, který je třeba zvážit při používání transformátorů. Hračka změny: Volba transformátorů se super nízkými ztrátami nechrání jen energii, ale také pomáhá chránit naše prostředí před škodlivými plyny vytvářenými při produkci energie pomocí fosilních paliv. Vysoká intenzita proudu může vést k různému výkonu různých typů transformátorů, což má za následek nižší účinnost celého elektrického systému. Je proto nezbytné vybrat vhodný transformátor podle úkolu a správně ho udržovat prostřednictvím pravidelné údržby, servisní péče a kalibrace, aby byla jeho funkčnost zachována ve nejlepším stavu.

Spolehlivost transformátorů je klíčová pro zajištění nepřetržitého fungování elektrické sítě; při selhání transformátoru ztratí část nebo celá funkčnost. Role spolehlivých transformátorů při dodávání nepřetržitého kvalitního elektřiny a ochrany vašeho zařízení před výkyvy, simplyfikacemi nebo jakýmkoli jiným typem pravděpodobných problémů je extrémně důležitá. Proto je velmi důležité podrobně zkoumat před nákupem distribučního nebo výkonového transformátoru. Jednou z hlavních úvah při výběru průmyslových transformátorů je volba transformátoru od renomovaných výrobců, kteří jsou známí svými transformátory s dobrým výkonem a spolehlivostí. Navíc bude údržba prováděná v souladu s pokyny výrobců pomáhat jejich neustálému fungování a lepšímu výkonu.

Při rozhodování o distribučních a výkonových transformátorech je třeba zvážit řadu takových životně důležitých faktorů. Zátěž transformátoru je jedním z nich, hlavně proto, že určuje, jaký výkon bude přenášen na různá místa. Správná úroveň izolace je důležitá, protože nás chrání před možnými selháním spojenými s nedostatkem správné izolace kvůli elektrickým poruchám nebo selhání zařízení. Dále je třeba sledovat teplotu provozu transformátoru, protože pokud teplota významně stoupne, může to vést k nestabilitě a zkrácení životnosti.

Distribuční transformátory a výkonové transformátory nejsou výjimkou; stejně jako počet národních standardů neustále roste, také se zvyšuje počet typů ochrany. Úmyslem těchto vývojů je udělat transformátory efektivnějšími, spolehlivějšími, bezpečnějšími a ekonomičtějšími pro jejich uživatele/organizace. Byly dosaženy některé významné inovace, které pomáhají překonat tento výzvu, včetně amorfních jádr transformátorů, které používají kovovou slitinu místo tradičního silikonského oceli, což může snížit energetické ztráty a zvýšit účinnost.

Dalším důležitým vývojem jsou suché transformátory, které používají vzduchové nebo plynové chlazení namísto kapalných dielektriků, jako je nafta. Suché transformátory jsou přirozeným vývojem v oblasti bezpečnosti, ekologickosti a nákladů spojených s jejich provozem.

Elektrické distribuční zařízení a transformátory jsou klíčovými součástmi elektrických sítí, které ovlivňují fungování elektrických systémů. S pomocí výběru vhodného typu transformátoru a pravidelné údržby budou majitelé (a provozovatelé) schopni zajistit efektivitu v oblasti dostupnosti elektřiny a ekonomické správy elektrické sítě v delších časových horizontech.

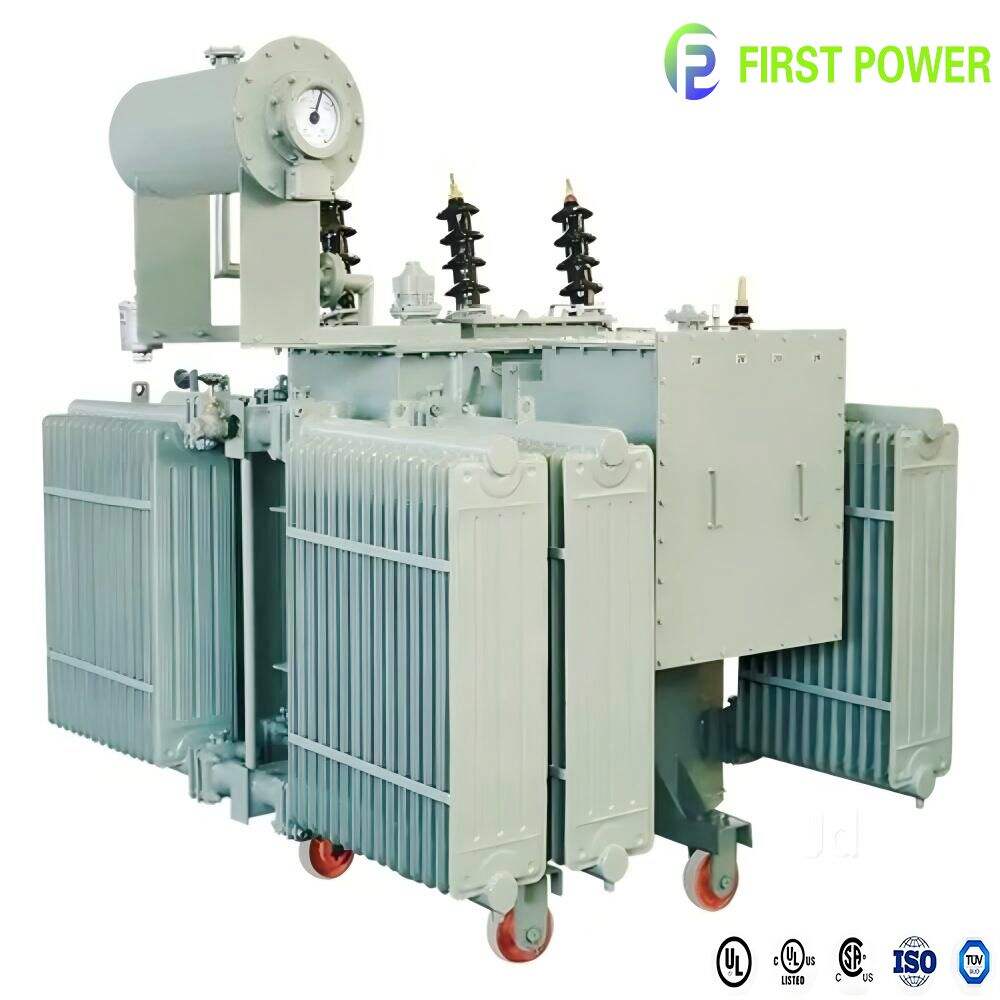

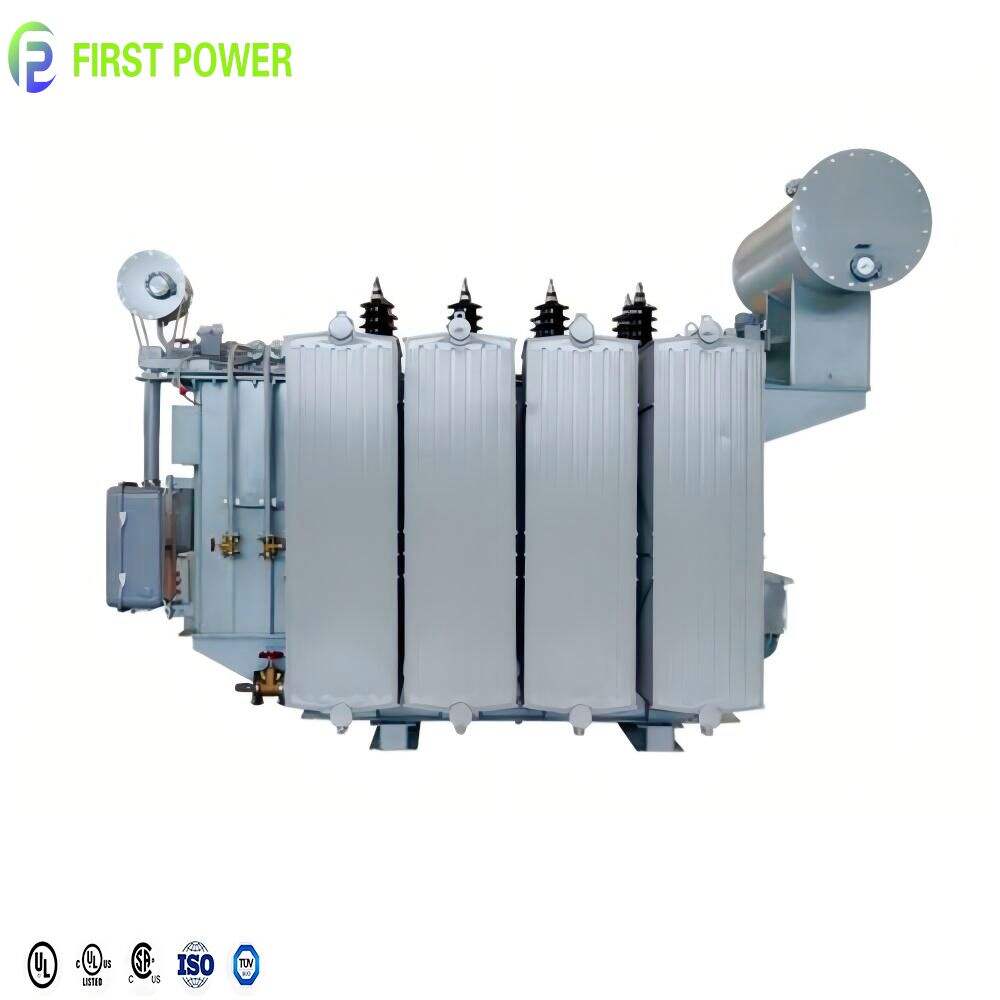

Máme více než tisíc zaměstnanců a přes padesát inženýrů, kteří se všichni zabývají distribucí a výrobou transformátorů v oblasti transformátorů, nabízejíce profesionální řešení a pomoc našim zákazníkům. Naše profesionální technická tým je kamenným základem našeho podnikání. Tento tým se skládá z vysoce kvalifikovaných inženýrů, návrhářů, techniků a odborníků na kontrolu kvality, kteří mají rozsáhlé znalosti a odbornost v technologii transformátorů. Jsou zavázáni sledovat poslední trendy a technologie v průmyslu, aby se zajistilo, že naše produkty jsou vždy aktuální a konkurenceschopné. Technický tým spolupracuje s našimi zákazníky na porozumění jejich potřebám a požadavkům, poskytujíce přizpůsobená řešení, která tyto požadavky splňují. Tým také spravuje celý výrobní proces od návrhu a inženýrství přes výrobu až po kontrolu kvality. To zajistí, že každý transformátor, který vyrobíme, je nejvyšší kvality a účinnosti.

Věříme, že distribuce a transformátory moci jsou důležité. Poskytujeme kompletní zákaznickou podporu po prodeji, abychom zajistili, že jsou naši klienti spokojeni se svým nákupem. Jsme zavázáni k poskytování rychlých a efektivních služeb, ať už jde o pomoc při instalaci, tipy na údržbu nebo technické řešení problémů. Jasně si uvědomujeme, že transformátory jsou klíčové součásti ve mnoha odvětvích. Proto se snažíme nabízet našim zákazníkům nejefektivnější a nejrychlejší řešení jakéhokoli problému, s kterým se mohou setkat. Naše týmy jsou vždy připraveny odpovědět na vaše otázky, poskytnout asistenci a zajistit, aby byly potřeby zákazníků splněny vždycky.

Naše produkty prošly všemi důkladnými kontrolami kvality a plně vyhovují mezinárodním standardům, mají průmyslové certifikace jako lSO, lEC, UL, CUL, CE atd. Jsme velmi hrdí na množství průmyslových certifikací. Tyto certifikace nejsou pouze ukazatelem závazku k jakosti a bezpečnosti; dokazují také dodržování mezinárodních standardů a zákonů. Produkty jsou podrobeny důkladným auditům a kontrolám, aby splňovaly nejvyšší normy výkonnosti, bezpečnosti a trvanlivosti. Certifikace zahrnují široké spektrum aspektů výroby transformátorů, včetně návrhů, materiálů a metod výroby. Certifikace dávají našim zákazníkům jistotu, že distribuční a silnoproudé transformátory, do kterých investují, jsou nejbezpečnějším a spolehlivým produktem, který je podporován společností, držící se nejpřísnějších průmyslových standardů.

Během posledních 18 let se společnost nacházela na popředí průmyslu transformátorů. Vlastníme vlastní výrobní zařízení a nabízíme širokou škálu přizpůsobených služeb. Během tohoto období jsme si vybudovali rozsáhlou základnu zkušeností, která nám umožnila zůstat před svými soutěžiteli. Postupně jsme sbírali výhody bohatého zkušeností a odborností, což nám umožňuje předvídat trendy na trhu a navrhovat inovativní řešení schopná splnit požadavky našich zákazníků. Naše odbornosti v oblastech návrhu produktu, výroby a kontroly kvality nám umožňují navrhnout a vyrobit transformátory, které nejsou pouze pevné, ale také splňují nebo překonávají průmyslové normy. Naše léta zkušeností nám pomohla vybudovat silné vztahy se dodavateli, zákazníky a partnery, což dále posiluje naše postavení na trhu s distribučními a energetickými transformátory.